A post by

Dr. Jörg Bückle

Freelance author and industry expert

Hop aroma from yeast cells? Targeted production of proteins, fats or vitamins from beverage production residues? Alternative use of existing production facilities? Precision fermentation makes all this possible. We take a look at the future of the beverage industry and reveal what you can already experience at drinktec.

Released on 20/08/2025

A post by

Dr. Jörg Bückle

Freelance author and industry expert

Five, eight, ten billion by 2050 – the world's population is growing and growing. This makes it increasingly difficult to provide the food needed to feed everyone. Traditional agriculture and classic production technologies in particular are reaching their limits here. New approaches must be devised and implemented.

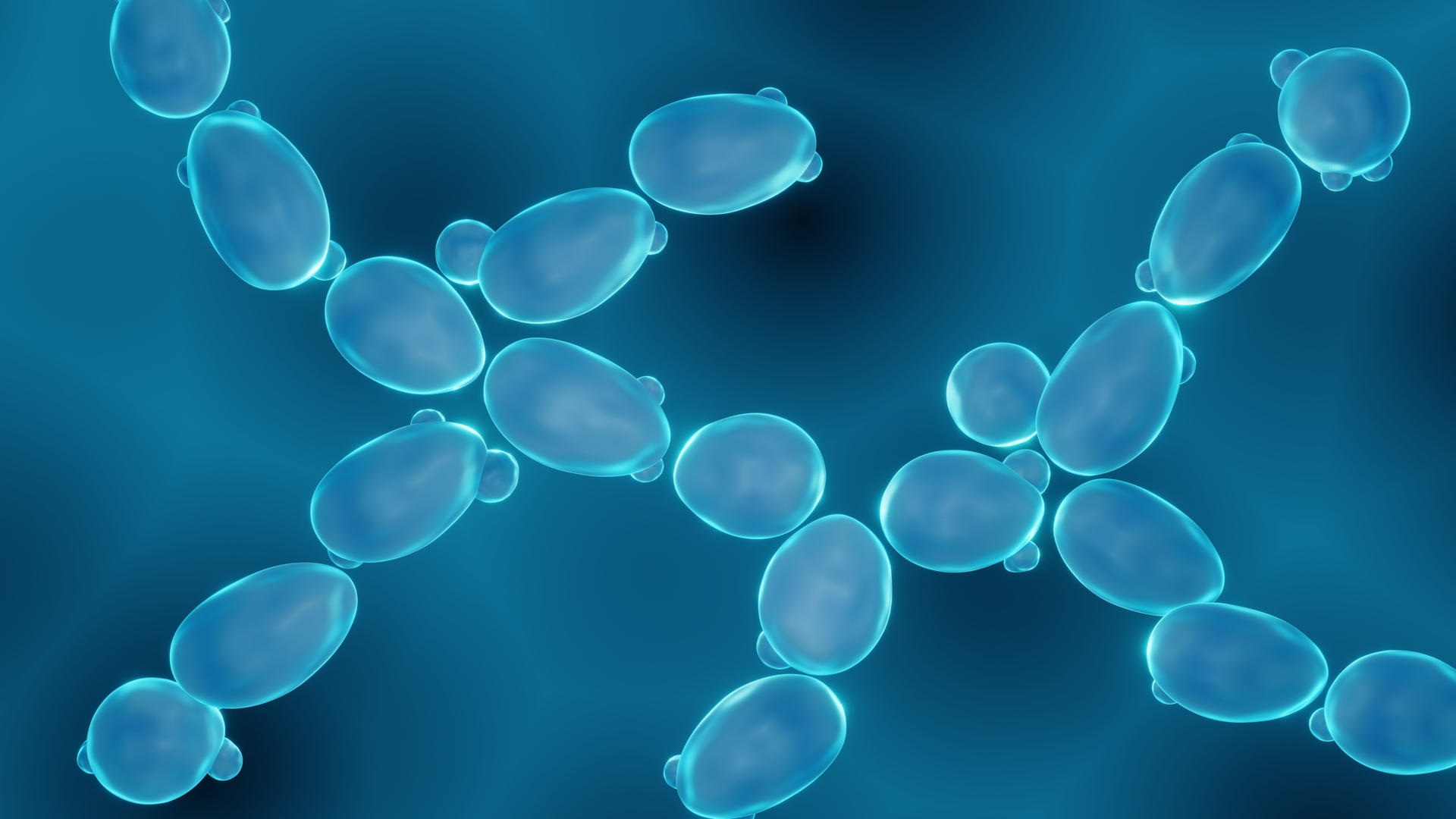

However, pure population growth is only one side of the coin at this turning point in history. At the same time, more and more consumers are eating sustainably. Sustainable in the sense of greater animal welfare, a smaller carbon footprint, lower resource consumption and entirely personal goals such as well-being and fitness. Against this backdrop, precision fermentation plays a key role in reconciling the key factors of availability, ecology, quality and economic efficiency. Selected or ‘reprogrammed’ microorganisms act as a kind of ‘biological mini-factory’ to produce the desired ingredients directly. With the identical properties of the original. Proteins, vitamins, enzymes, pigments, fats and flavours are just a few examples.

Fermentation has probably been with us since the dawn of time. Beer, wine, sourdough and kimchi are prime examples. In principle, fermentation involves microorganisms producing one or more new substances from a starting substrate.

This is how sugar is converted into alcohol or lactic acid. Precision fermentation now goes one step further: through selection or genetic reprogramming, microorganisms in a bioreactor can produce a wide range of food and pharmaceutical ingredients from a substrate under narrowly specified process parameters. These ingredients offer users a colourful bouquet of possibilities.

Precision fermentation has long made it possible to produce cheese varieties or burger patties from proteins that have never come into contact with animals – and they taste great too. This is an extremely attractive market: the Boston Consulting Group and impact investor Blue Horizon, for example, expect alternative proteins alone to generate sales of 290 billion US dollars along the value chain by 2035.

Trade visitors to drinktec in Munich will be able to experience a very current example first-hand – an innovative hop aroma produced using a patented precision fermentation process.

Instead of relying on traditional hop cultivation, which is resource-intensive and heavily dependent on weather conditions, harvest cycles and supply chains, this approach uses specially selected yeast strains that fermentatively produce the same aroma compounds found in hops. The result is a sustainable, reliable and high-quality hop aroma that meets the growing demands of the beverage industry for availability, consistent quality, efficiency and environmental responsibility. The aroma is suitable for both alcoholic and non-alcoholic beers and also enables producers to create new lifestyle products. Although the focus here is clearly on hop aromas, this example also demonstrates the broad potential of precision fermentation for the production of natural, high-quality flavours that go beyond the limits of agricultural production. It opens the door for the beverage and liquid food industry to offer consumers exceptional sensory experiences while protecting natural resources.

With the drinkec Innovation Guide, you can discover the details of this exciting practical example on site.

You can find out more about precision fermentation on Monday, 15 September 2025 at the Liquidrome Wave Stage. Stay tuned ...

The bioreactor is the most important component of precision fermentation in terms of process engineering. On the one hand, it must be able to precisely implement the highly individual process parameters of the microorganisms, such as substrate supply, temperature, ventilation or the use of an agitator. In addition, these bioreactors, just like the process tanks installed, meet the highest standards in terms of hygienic design and cleanability. HACCP requirements, recommendations of the European Hygienic Engineering & Design Group (EHEDG) and surface roughness of less than 0.3 μm are important keywords here.

But what exactly can a producer expect from precision fermentation? These include greater flexibility in production processes, increased efficiency, improved cost efficiency thanks to low TCO and CAPEX, reduced methane and CO2 emissions, and lower energy and water consumption compared to conventional approaches. In short, the production of proteins, fats or vitamins is significantly faster, more efficient, more controlled and more climate-friendly than with conventional methods such as the ‘detour’ via livestock. Precision fermentation also allows large areas that are currently used for intensive agriculture to be freed up for climate protection.

There are many good arguments in favour of using a ‘biological mini-factory’ – and the response is growing: on 17 July 2025, the GEA Group opened a new New Food Application and Technology Centre of Excellence (ATC) in the USA. Eighteen million euros have been invested in the Group's second technology centre, which paves the way for manufacturers to move from the idea stage to the industrial production of alternatives to conventional foods such as meat, dairy products, fish and eggs. A key component is a pilot plant for precision fermentation. ‘The food industry is at a turning point. To feed future generations sustainably, we must turn promising concepts into industrial reality,’ says Stefan Klebert, CEO of the GEA Group. ‘With this investment, we are helping our customers to implement the large-scale production of novel foods such as precision-fermented protein.’ The turning point has therefore long since gained momentum.

Highlights

A post by Susanne Blüml

Read more

Water treatment

A post by Susanne Blüml

Read more

drinktec key topic

A post by Susanne Blüml

Read more

Market data

A post by Susanne Blüml

Read more